Premier Aluminum Llc - The Facts

Table of ContentsPremier Aluminum Llc Fundamentals ExplainedExamine This Report on Premier Aluminum LlcPremier Aluminum Llc for DummiesNot known Details About Premier Aluminum Llc

(https://premieraluminum.godaddysites.com/f/why-premier-aluminum-llc-is-the-best-aluminum-casting-company)Traditionally, a purchaser's main duty was to find competent and receptive distributors. Sometimes, purchasers thought that any distributor happy to contractually fulfill the purchase requirement was certified. However, utilizing reduced price and unqualified vendors can cause quality issues, and lost time and money in the long run. To help you through the process, right here are some points to consider when selecting the ideal metal spreading vendor.

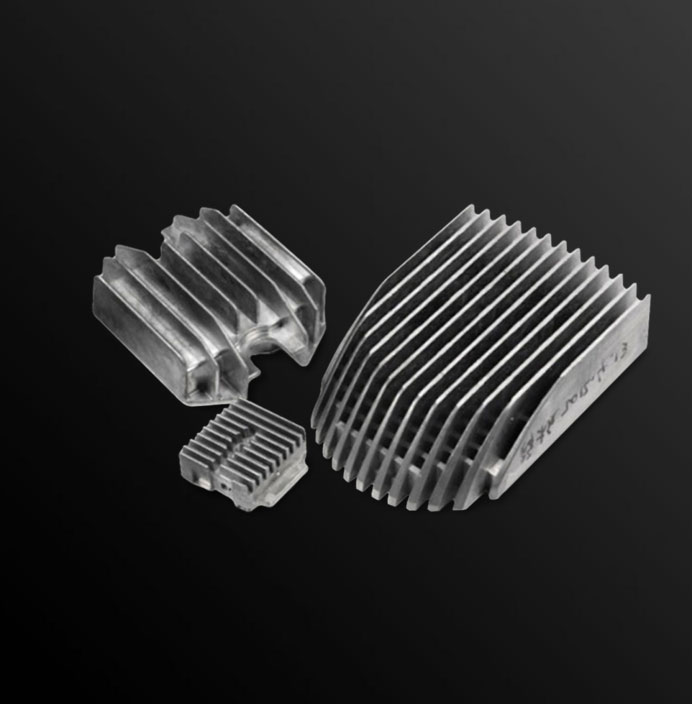

A company that only utilizes the investment spreading procedure will certainly try to offer you on why that process is best for your application (Aluminum Foundry). However what happens if making use of the sand casting procedure is best for you and your demands? Rather, seek a distributor that offers a variety of casting procedures so the most effective alternative for YOU is picked

If working with a single source for all of your casting requires is important to you, the provider needs to be diverse in its abilities. When incorporated with other incorporated abilities, this can assist streamline and press the supply base. When selecting the appropriate spreading distributor, careful factor to consider needs to be provided to top quality, service, and rate.

Getting My Premier Aluminum Llc To Work

Purchasers increasingly pick spreading vendors who have machining capacities. This can prevent dispute if defects are discovered throughout machining. If a third party is machining, it might lead to "finger-pointing" about who is at fault. Is it a spreading problem or a machining issue? If the casting vendor discovers a concern during machining, the problem is dealt with much faster without any dispute over whose mistake it is.

What do you require from your casting vendor? Are you looking for a person to simply deliver a metal component to your doorstep or do you need much more?

Some shops are limited or specialized. Make sure the provider can meet all your product or alloy requirements to eliminate the need for numerous suppliers.

Not known Facts About Premier Aluminum Llc

Study the vendor's site. Talk to a sales representative or business affiliate. Ask a great deal of questions. Visit their center. Get an understanding of what they can do for you and read this if you can see on your own developing a strong, common relationship with them.

Aluminum is also lightweight and has good corrosion resistance, making it perfect for applications where weight and toughness are essential variables. Additionally, light weight aluminum casting is a cost-effective technique of production, as it requires less energy and resources than various other methods. Iron spreading, on the various other hand, includes putting liquified iron into a mold to produce a wanted shape.

The Ultimate Guide To Premier Aluminum Llc

Iron casting is likewise able to withstand high temperatures, making it suitable for use in applications such as engine parts and industrial machinery. Nonetheless, iron spreading can be much more costly than light weight aluminum casting due to the greater expense of raw materials and the energy called for to thaw the iron. When deciding in between aluminum spreading and iron spreading, it is essential to consider the specific needs of the application.

In verdict, both light weight aluminum casting and iron spreading have their own unique benefits and downsides. There are 3 sub-processes that fall under the classification of die spreading: gravity die casting (or irreversible mold and mildew casting), low-pressure die spreading and high-pressure die casting. To get to the ended up product, there are 3 key alloys made use of as die casting product to choose from: zinc, aluminum and magnesium.